大流量真空产生器(ML、X系列)

供應情形: 有現貨

型號: EDCO-01

美国EDCO USA 【多段式超静音】 大流量真空产生器(气动式真空帮浦)

美国EDCO USA 大流量真空产生器(气动式真空帮浦),可替代传统马达式真空帮浦或鼓风机,利用压缩空气的驱动,快速产生大流量真空,达到相当于传统马达真空帮浦1/2~24HP的马力, 并且没有马达式真空帮浦吵杂、发热、易故障等问题。零故障设计结构与铝合金机械材质,可以免除您在维修、保养,以及移动、装置上的困难;超静音真空帮浦运转设计,干净、无声,最适合半导体产业、高科技产业等需极度干净、安静的工作环境使用;并可搭配多种真空产生器模块,使用方面更加便利、自由。

另有大流量【L】型、低压力【M】型、高性能复合【ML】型、超大流量【E】型、高真空【X】型等多款流量机型,以及泛用型、耐高温型机种可供选择。

压缩空气驱动

压缩空气驱动,可快速产生大流量真空,相当于1/2 ~ 24HP马力之马达式真空帮浦,适用于防爆、或需要大流量、或工作环境要求干净、安静的真空应用场合,以替代马达式真空帮浦或鼓风机。

超静音、低耗气量、大抽气量

没有马达式真空帮浦的吵杂运转声、震动、发热和油气问题。零故障结构,不需定期保养、加油及维护。真空抽气量每分钟203~9742公升,最高真空度可达-718mmHg。

铝合金本体

坚固耐用的铝合金本体,体积小重量轻,可拆开清洗内部组件。随处安装不受空间限制,减少配管损失及机台体积、重量。可依实际真空流量需求任意增减产生器模块,不需担心选购错误问题。

电磁阀快速切换

可籍由电磁阀快速切换,控制真空的产生与破坏,大量提高生产速度及效率并可节省能源。

多种型号选择

有大流量【L】型、低压力【M】型、高性能复合【ML】型、超大流量【E】型、高真空【X】型多重选择。

工作温度范围

泛用型 -1~+82℃

耐高温型 -10~+232℃。

代表性的应用

玻璃、PCB板、其他透气或不透气薄片(板材)的真空夹持、切割、测试设备;真空吊重;粉体输送;物品的真空包装;橡、塑料真空成型、射出的抽真空;液体充填;

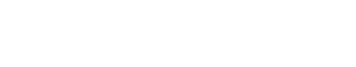

经典型真空产生器产品结构

CLASSIC PUMPS MULTI-STAGE PUMPS:PRINCIPLE OF OPERATION

MULTI-EJECTOR

Larger capacity vacuum pumps are created by placing identical nozzle sets in a parallel configuration, either in the same body or in a stacking module. Additional vacuum flow capacity is attained but maximum vacuum level is not affected since that is determined by the nozzle series. This method provides a specific repeatable increment of capacity increase that is very handy when sizing a pump for an application since the basic shape of the performance curve doesn't change. Vacuum flow and air consumption is increased in proportion to the number of nozzle sets, and system evacuation time is decreased proportionately.

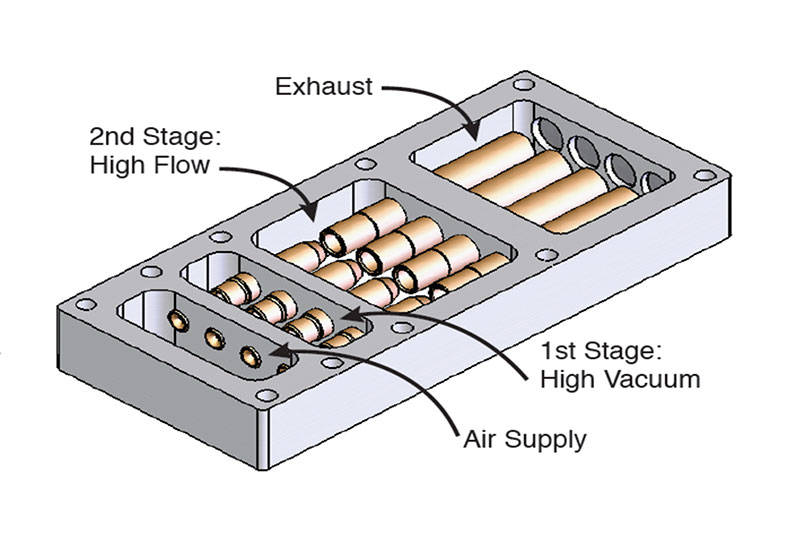

HIGH FLOW MODE

An air supply to the pump is turned on and high-pressure air flows thru the first nozzle, generating a vacuum flow when it passes into the second nozzle. As air is evacuated from the system,induced air flows into the vacuum port and is drawn into the first stage ejector (gap between first and second nozzles) and combines with the compressed air flow from the first nozzle before passing into the second stage ejector (gap between second and third nozzle). The powerful combind airflow induces a high vacuum flow rate thru the second stage ejector until the increasing vacuum level causes the flap check valve to close. The valve closing point is dependent on nozzle series (A, E, L, M, ML, or X) and the operating air pressure. For example at 87 psi the flap valve will close at 11" Hg for an ML-series pump and at 18'' Hg for an E-series pump. This closing is evident by the change in slope of the performance curve.

| # | 名稱 | 上传日期 | 名称 | 下载 |

|---|---|---|---|---|

| 1 | 产品型录 | 2019-09-17 | 产品型录 |